Tiùb coiled alùmanum 1060

Tiùb coil alùmanum ASTM B210 1060 airson Evaporator

Tha 1060 alùmanum alloy na alloy stèidhichte air alùmanum anns an teaghlach obraichte “fìor-ghlan gu malairteach” (sreath 1000 no 1xxx).Tha e gu bunaiteach glè choltach ri 1050 alùmanum alloy, leis an eadar-dhealachadh a’ tighinn sìos gu 0.1% alùmanum a rèir cuideam.

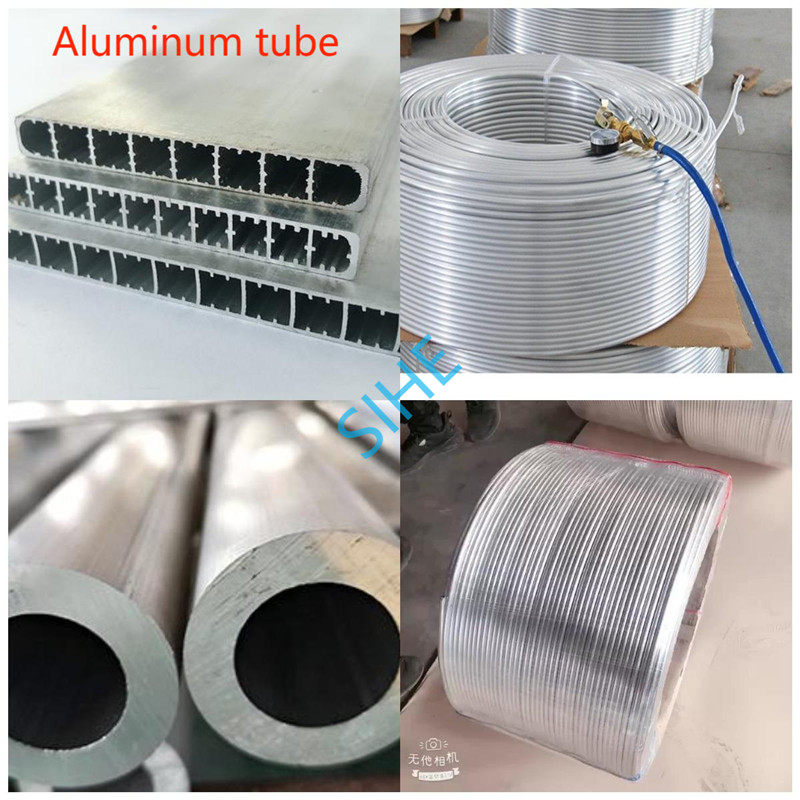

Tiùb alùmanum airson gnìomhachas HVAC&R.tha uachdar an tiùb coiled rèidh, gun phòlaichean, gun chaitheamh, agus tha nitrigin air a chumail suas.tha tiùban alùmanum gu sònraichte freagarrach airson ruith toraidh fada airson tagraidhean gnìomhachais.Sa mhòr-chuid air a chleachdadh air an èadhar-conditioner, reothadair, fuarachaidh, Condenser, intercooler, evaporator, blàth gaoithe gluasad, adhair conditioner loidhne-phìoban, càr radiator, etc.

1 .Alloy: ASTM B241 1050/1060/1070

2. Teòthachd: O/H12/H14/H16/H22/H24/H26/H112/F

3. Tighead: 0.7mm--1.5mm

4. Trast-thomhas: a rèir riatanasan luchd-cleachdaidh

5. Tolerance: +/- 0.05mm

6. Iarrtas: adhair conditioner, refrigerator, rolla-bond evaporator, teas iomlaidear, gas àmhainn, condenser, agus intercooler agus mar sin air adhart.

7. Pasgan: Màileidean fiodha no bogsaichean a tha freagarrach airson còmhdhail mara air astar, faodar a ghnàthachadh le teachdaichean.

Sònrachaidhean

| A1050 Aluminium Chemical composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | cuid eile |

| 99.5~100 | 0~0.25 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.40 | 0~0.03 |

| A1060 Aluminium Chemical composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | cuid eile |

| 99.6-100 | 0~0.25 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.03 | 0~0.03 | / | 0~0.35 | |

| A1070 Aluminium Chemical composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | cuid eile |

| 99.7~100 | 0~0.2 | 0~0.04 | 0~0.03 | 0~0.04 | 0~0.03 | 0~0.03 | 0~0.05 | 0~0.25 | |

| Seilbh Corporra de phìob tiùb alùmanum 1050 1060 1070 | ||||||

| Alloy | Teòthachd | Tighead balla | Toradh deuchainn teòthachd an t-seòmair | |||

| Neart teannachaidh / MPa | Neart toraidh / MPa | Leudachadh/% | ||||

| A50mm | A | |||||

| Chan eil nas lugha na | ||||||

| 1050 | Ach, H111 | Uile | 60 ~ 100 | 20 | 25 | 23 |

| H112 | Uile | 60 | 20 | 25 | 23 | |

| F | Uile | - | - | - | - | |

| 1060 | O | Uile | 60 ~ 95 | 15 | 25 | 22 |

| H112 | Uile | 60 | - | 25 | 22 | |

| 1070 | O | Uile | 60 ~ 95 | - | 25 | 22 |

| H112 | Uile | 60 | 20 | 25 | 22 | |

barantas meud

1) coltas uachdar: uachdar glan còmhnard gun iomlan, sgrìobadh, ola salach no oxidation.

2) ùr-nodha: oir gearraidh grinn gun burrs.

3) Amas càileachd: is e an ìre barrantaichte sgrùdadh toraidh frist 98%. sàsachd luchd-cleachdaidh le 95%.

| A1050 Aluminium Chemical composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | cuid eile |

| 99.5~100 | 0~0.25 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.40 | 0~0.03 |

| A1060 Aluminium Chemical composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | cuid eile |

| 99.6-100 | 0~0.25 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.03 | 0~0.03 | / | 0~0.35 | |

| Compositio Ceimigeach Alùmanum A1070n | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | cuid eile |

| 99.7~100 | 0~0.2 | 0~0.04 | 0~0.03 | 0~0.04 | 0~0.03 | 0~0.03 | 0~0.05 | 0~0.25 | |

| A3003 Aluminium Chemical composition | |||||||

| Al | Si | Cu | Zn | Mn | Fe | Cuid eile Singilte | |

| cuid eile | 0~0.6 | 0.05 ~ 0.20 | 0~0.1 | 1.0~1.5 | 0~0.70 | 0~0.05 | |

| Alloy | Teòthachd | Sònrachadh | |||

| Tighead(mm) | Trast-thomhas(mm) | Neart tensile | cruas | ||

| 7075 7005 (tiùb) | T5, T6, T9 | >0.5 | 5.0-80 | > 310 Mpa | >140 |

| 6061 6063 (pròifilean) | T5, T6 | >1.6 | 10-180 | > 572 Mpa | HB90-110 |

| Fad: <6 Meatair | |||||

| TEAMAID | Tiugh (mm) | STRAGTH TENSILE | ELONGATION % | Inbhe |

| T5 | 0.4-5 | 60-100 | ≥20 | GB/T3190-1996 |

Bathar alùmanum